Managing Inventories

Learn how to create, track, and manage inventory items with complete visibility of their lifecycle, status, and transactions.

Overview

The Inventories feature provides a robust system for managing your organization's inventory items. It enables you to:

- Track materials across different locations

- Maintain accurate stock levels with transaction history

- Monitor item status and availability

- Manage batch and serial number tracking

- Record important dates and ownership information

Key Features

- Complete Inventory Tracking: Create and monitor inventory entries with detailed information about materials, locations, and quantities

- Status Management: Track item availability and condition using customizable status types

- Transaction History: Maintain a complete audit trail of all inventory changes and movements

- Batch/Serial Tracking: Support for both batch and individual item tracking with unique identifiers

- Flexible Ownership: Assign and transfer ownership of inventory items

- Barcode Integration: Generate and manage barcodes for efficient inventory handling

Creating an Inventory Entry

-

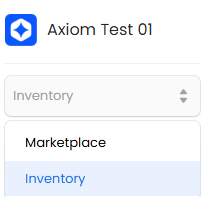

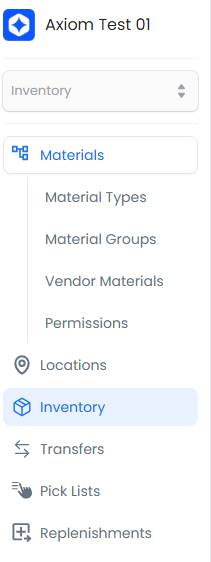

Access inventories:

- Click "Inventory" on the landing page

- Select "Inventory" from the sidebar menu

-

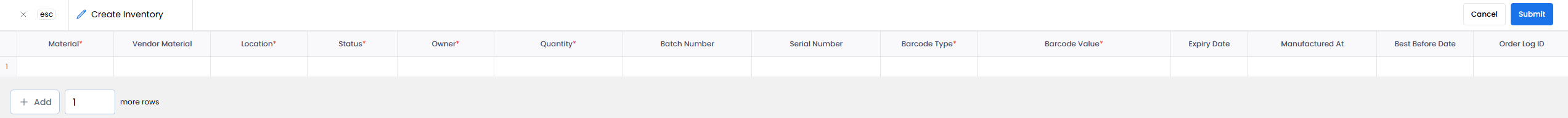

Create new inventory:

- Click "Create Inventory"

-

Fill in inventory details:

Required Fields

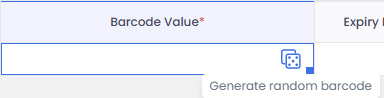

Field Input Type Description Material Search dropdown Select the material to add - links to the material master data with specifications Location Search dropdown Choose storage location - determines where the inventory physically resides Status Search dropdown Current item status (Available/Unavailable) - controls whether items can be used/transferred Owner Search dropdown Assign ownership - determines who has control and responsibility for the inventory Quantity Manual input Amount of material - triggers a transaction record for audit trail Barcode Type Search dropdown Type of barcode used - supports various formats for tracking and identification Barcode Value Manual input/Generate Unique identifier - can be manually entered or automatically generated

Optional Fields

Field Input Type Description Vendor Material Search dropdown Link to supplier's material code for cross-reference Batch Number Manual input For batch-tracked materials - enables traceability of production lots Serial Number Manual input For serialized items - enables tracking of individual units Expiry Date Manual input Date when the material becomes invalid for use Manufactured At Manual input Production date - important for quality and warranty tracking Best Before Date Manual input Recommended usage date - for materials with degrading quality Order Log ID Search dropdown Links inventory to its originating purchase or transfer order -

Complete the entry:

- Click "+ Add" to enter more inventories

- Click "Submit" to save current entry

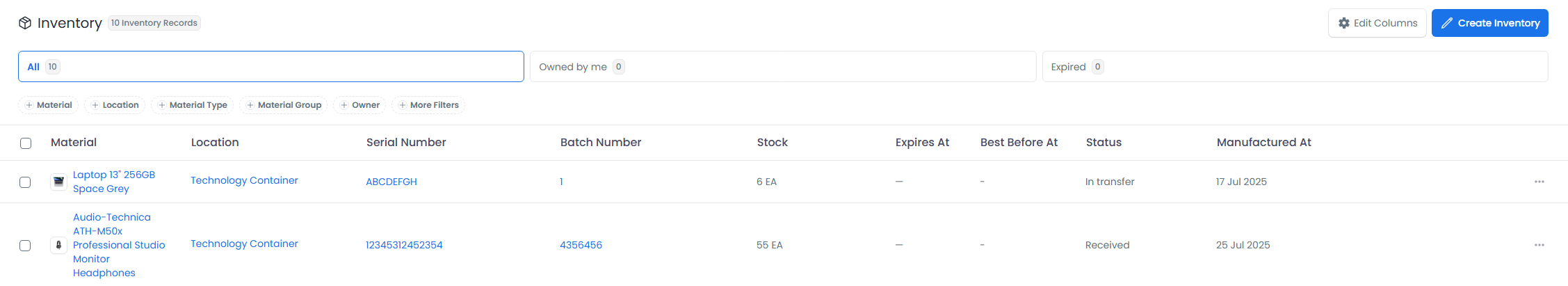

Your new inventory entry will appear in the main inventory list:

Best Practices

Data Entry

- Always verify material and location information before creating inventory entries

- Use consistent naming conventions for batch and serial numbers

- Include detailed notes when making manual quantity adjustments

- Double-check barcode values to ensure accuracy

Status Management

- Choose appropriate status types that reflect the actual state of inventory

- Update status promptly when inventory condition or availability changes

- Use status notes to explain any special conditions or restrictions

Tracking and Traceability

- Enter batch/serial numbers immediately when receiving tracked materials

- Record all relevant dates (expiry, manufacture, best before) for time-sensitive items

- Link inventory to source documents (purchase orders, transfer orders) when available

Inventory Maintenance

- Regularly review and update inventory records

- Perform physical counts to verify system quantities

- Monitor expiry dates and take action on aging inventory

- Keep location assignments current and accurate

TIP

When creating multiple inventory entries, use the "+ Add" button to efficiently enter all items before final submission. This creates a single transaction batch for better traceability.