Inventory Replenishments

Learn how to set up and manage automated inventory replenishment to maintain optimal stock levels across your locations.

Overview

The Replenishments feature provides an intelligent system for automatically restocking inventory when levels fall below predefined thresholds. It supports both automated and manual workflows to ensure you always maintain optimal stock levels across all locations.

Key Features

- Automated Monitoring: System continuously checks inventory levels against refill points

- Multiple Fulfillment Methods: Support for transfers, purchases, and manual replenishment

- Flexible Triggers: Set custom refill points based on your needs

- Progress Tracking: Monitor replenishment status from creation to completion

- Priority Management: Define urgency levels and fulfillment preferences

Replenishment Methods

Transfer-Based

- Move stock between locations within your organization

- System validates source location stock availability

- Automated transfer order creation and processing

- Real-time stock updates at both locations

Purchase-Based

- Automatically create purchase orders when needed

- Track order progress through completion

- Integrate with supplier management

- Update inventory upon receipt

Manual

- Create replenishment events manually

- Override automated settings when needed

- Handle special cases and exceptions

- Full control over the process

Creating a Replenishment

-

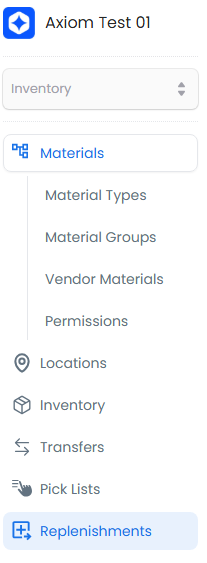

Access replenishments:

- Click "Inventory" on the landing page

- Select "Replenishments" from menu

-

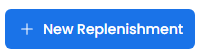

Start new replenishment:

- Click "+ New Replenishment"

-

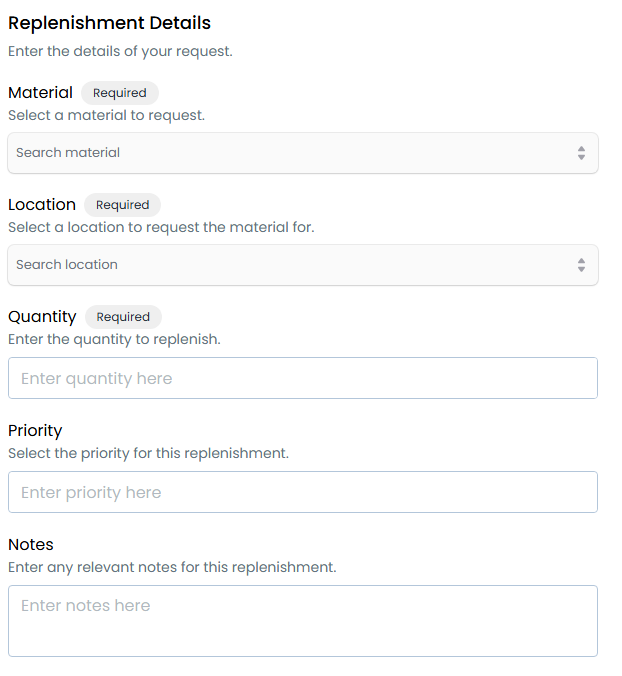

Enter replenishment details:

Required Fields

Field Description Material Select the item to replenish - links to material master data Quantity Specify amount to add - consider usage patterns and lead times Location Choose target location - where stock will be delivered Supplier Select source supplier - for purchase-based replenishment Optional Fields

Field Description Priority Set urgency level - affects processing order Refill Point Minimum stock level that triggers automatic replenishment Refill Method Preferred fulfillment method (transfer, purchase, or manual) Source Location For transfer-based replenishment - where stock will come from Notes Additional instructions or context for the replenishment -

Complete the replenishment:

- Review details

The replenishment will be created and appear in your replenishments list with its current status:

Best Practices

Setting Up Replenishment Points

- Calculate refill points based on historical usage patterns

- Consider lead times for different fulfillment methods

- Include safety stock requirements in calculations

- Review and adjust points periodically based on demand changes

Configuring Fulfillment Methods

- Set up multiple fulfillment methods for flexibility

- Define source location priorities for transfers

- Configure backup suppliers for purchases

- Enable fallback options for critical items

Managing Replenishments

- Monitor replenishment status regularly

- Address failed replenishments promptly

- Keep supplier and location information current

- Document special handling requirements in notes

Performance Monitoring

- Track replenishment completion rates

- Measure average fulfillment times

- Monitor stock-out incidents

- Review manual intervention frequency

TIP

When setting up automated replenishment, start with a small set of frequently used items to test and refine your settings before expanding to your full inventory.