Material Imports

Learn how to efficiently manage your materials catalog through bulk imports and updates using CSV files.

Overview

The Material Import feature provides a powerful way to manage large numbers of materials efficiently. This tool helps you:

- Add or update hundreds of materials at once

- Maintain data consistency across your catalog

- Save time compared to manual entry

- Process changes in the background

- Track and verify all updates

Key Features

- Bulk Operations: Handle multiple materials in a single operation

- Background Processing: Continue working while imports run

- Progress Tracking: Monitor import status and results

- Data Validation: Ensure data accuracy before import

- Flexible Updates: Create new or update existing materials

Benefits

Time Efficiency

- Reduce manual data entry

- Process large catalogs quickly

- Update multiple fields at once

- Automate repetitive tasks

- Handle bulk changes efficiently

Data Quality

- Consistent data formats

- Validated information

- Complete material records

- Accurate relationships

- Traceable updates

Prerequisites

Before starting an import, ensure you have:

- Valid Material Groups in your store

- Valid Units of Measure (UOM) in your store

- Your material data prepared in CSV format

TIP

The import will fail if referenced Material Groups or UOMs don't exist in your store.

Importing Materials

To import materials:

- Select

Inventoryfrom the landing page dropdown

- Click

Importon the Materials landing page

- Download and fill out the template

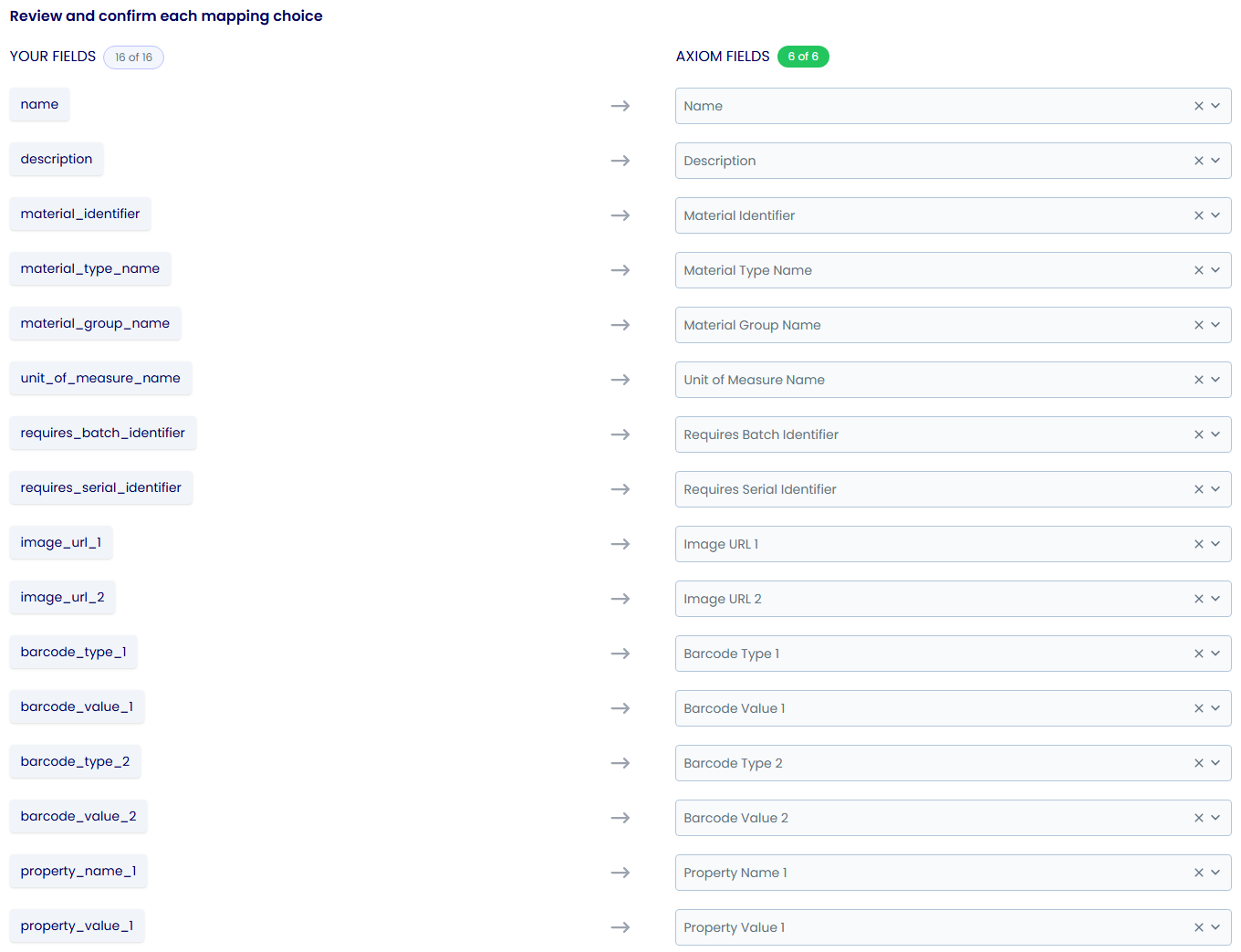

- Upload your completed CSV file

- Map your fields and click

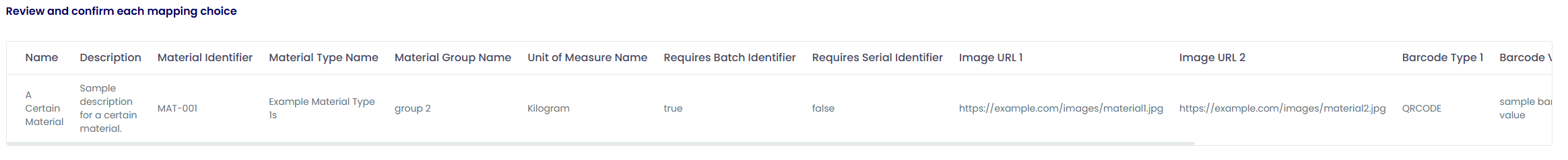

Continue

- Review your data and click

Submit

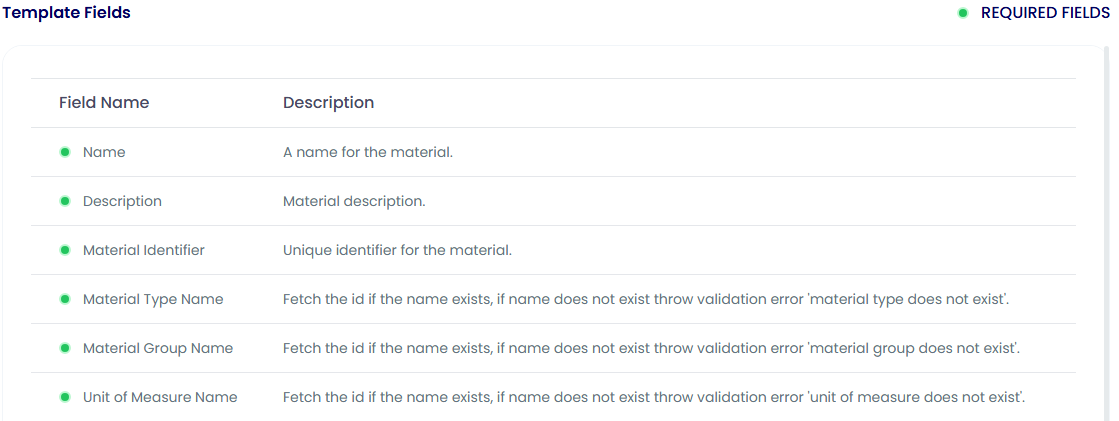

CSV Template Fields

Required Fields

| Field | Description |

|---|---|

| name | Descriptive name that clearly identifies the material |

| material_identifier | Unique identifier used for updates - must be consistent across systems |

| material_group_name | Valid group name from your store - organizes materials logically |

| unit_of_measure_name | Valid UOM from your store - ensures consistent quantity measurements |

Optional Fields

| Field | Description |

|---|---|

| description | Detailed description of material characteristics and usage |

| material_type_name | Must match existing type - defines material properties and validation |

| requires_batch_identifier | Set to "true" for batch-tracked materials, "false" otherwise |

| requires_serial_identifier | Set to "true" for serialized materials, "false" otherwise |

| image_url_1 to image_url_5 | Valid URLs for material images - helps with visual identification |

| barcode_type_1/value_1 to type_5/value_5 | Pairs of barcode type and value for material tracking |

| property_name_1/value_1 to name_5/value_5 | Custom property pairs for additional material attributes |

| common_part_number_1 to number_5 | Alternative part numbers for cross-referencing |

Field Guidelines

Material Names

- Use clear, descriptive names

- Follow consistent naming conventions

- Include relevant specifications

- Avoid abbreviations unless standard

- Keep names concise but meaningful

Identifiers

- Use consistent identifier formats

- Ensure uniqueness across systems

- Include relevant prefixes if needed

- Document identifier structure

- Maintain identifier history

Groups and Types

- Verify group existence before import

- Use correct group names exactly

- Match type names precisely

- Consider group hierarchies

- Plan for future categorization

Custom Properties

- Use standardized property names

- Provide complete property pairs

- Follow value format requirements

- Document property purposes

- Consider reporting needs

TIP

For barcode types, use standard formats like QR Code, PDF417, Data Matrix, Code 39, Code 128, GS1-128, EAN-8/13, UPC-A/E.

Import Process

During import:

- Each row is validated for required fields and data format

- System checks material_identifier:

- New identifiers create materials

- Existing identifiers update materials

- Images, barcodes, and properties are applied

- Results are available in the import history

Update Behavior

When updating existing materials:

- Barcodes are completely replaced with new values

- Image URLs are refreshed from the CSV

- Properties are replaced with new values

- Material type changes may be blocked if required fields exist

Troubleshooting

Common errors and solutions:

- "Material group does not exist": Create the group first

- "Unit of measure does not exist": Add the UOM first

- "Material type does not exist": Fix the type name or leave blank

- Invalid barcode type: Use standard format

- Boolean fields: Use exactly "true" or "false"

- Image URLs: Must be valid web links

Best Practices

Preparation

- Back up your data before large imports

- Test with a small sample first

- Verify all referenced data exists

- Clean and validate your CSV data

- Document your import process

CSV File Management

- Use the provided template

- Keep consistent column order

- Validate data formats

- Remove duplicate entries

- Save backups of import files

Import Process

- Start with small batches

- Monitor import progress

- Review error messages carefully

- Document any issues encountered

- Keep import logs for reference

Data Validation

- Check required field values

- Verify field relationships

- Validate data formats

- Review special characters

- Test complex field values

Post-Import

- Verify imported records

- Check relationships

- Test material functionality

- Document any issues

- Update related records

TIP

When updating existing materials, consider exporting the current data first. This provides a backup and helps you understand the existing data structure.

- Overview

- Key Features

- Benefits

- Time Efficiency

- Data Quality

- Prerequisites

- Importing Materials

- CSV Template Fields

- Required Fields

- Optional Fields

- Field Guidelines

- Material Names

- Identifiers

- Groups and Types

- Custom Properties

- Import Process

- Update Behavior

- Troubleshooting

- Best Practices

- Preparation

- CSV File Management

- Import Process

- Data Validation

- Post-Import