Material Groups

Learn how to create and manage material groups to logically organize your inventory and improve operational efficiency.

Overview

Material Groups provide a powerful way to categorize and organize materials in your inventory system. This structured approach helps:

- Keep your inventory neatly organized

- Find materials quickly and efficiently

- Generate meaningful reports by category

- Apply consistent procedures to similar items

- Simplify training for new employees

Key Features

- Logical Organization: Group similar materials based on common characteristics

- Clear Structure: Each material belongs to exactly one group

- Flexible Categories: Create groups that match your business needs

- Quick Access: Filter and search materials by group

- Enhanced Reporting: Analyze inventory performance by category

Benefits

Operational Efficiency

- Find materials faster through categorized searches

- Apply bulk operations to similar materials

- Streamline purchase orders by group

- Maintain consistent procedures

Inventory Management

- Keep materials organized logically

- Track inventory levels by category

- Monitor performance metrics by group

- Identify trends and patterns

Business Intelligence

- Generate category-based reports

- Analyze inventory by group

- Make informed stocking decisions

- Track category performance

To access material groups, navigate to the Inventory section from the landing page by selecting 'Inventory' from the dropdown menu in the top left corner.

Creating Material Groups

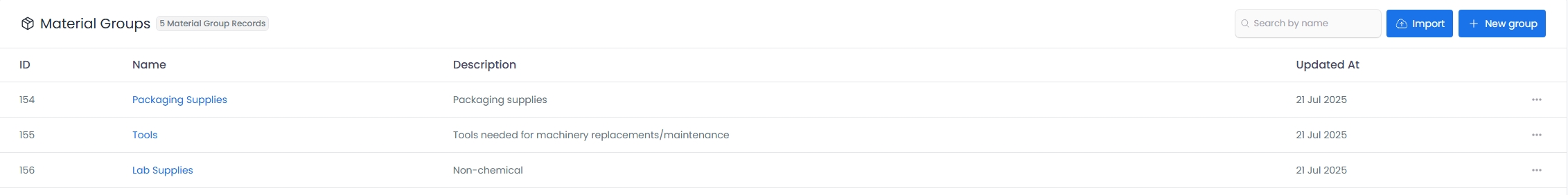

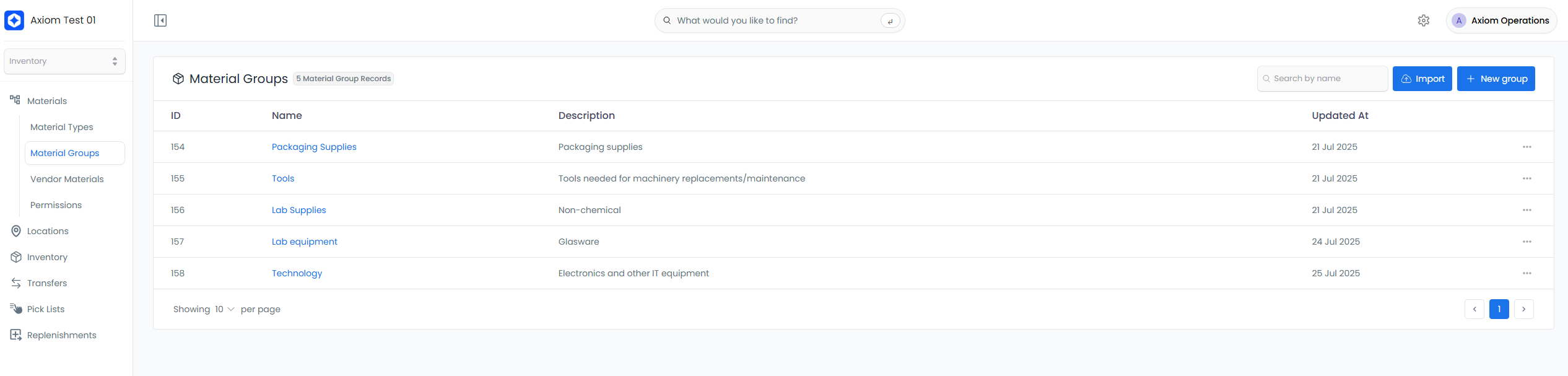

- Select Material Groups from the Inventory section menu to access the groups management page:

You have two methods available for creating material groups:

Method 1: Manually Add a New Group

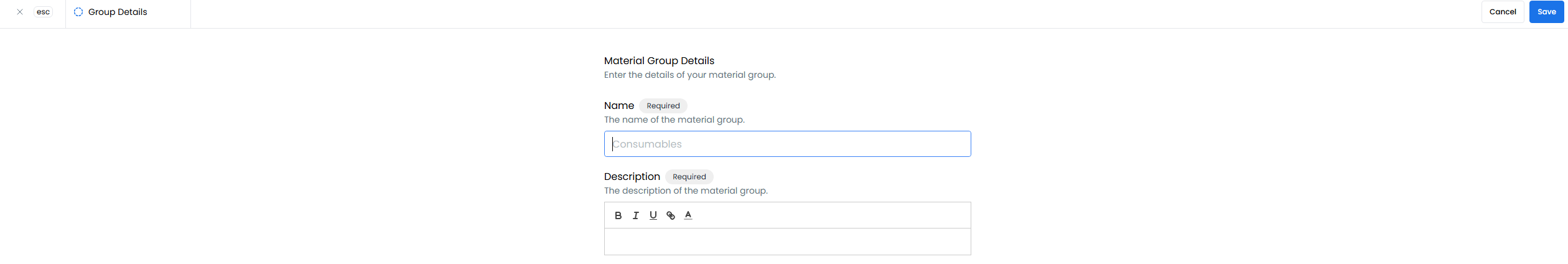

- Click the + New Group button to start creating a new material group manually:

-

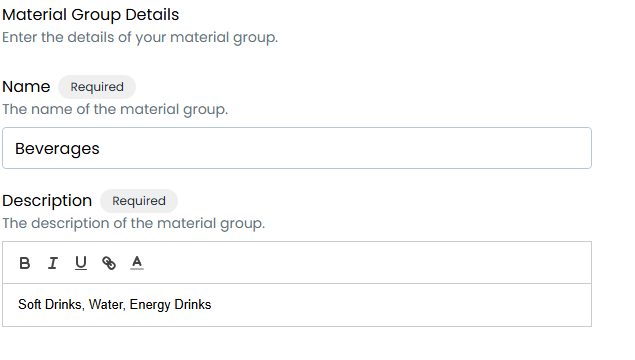

Complete the Material Group Details form with the following information:

Required Fields

Field Description Name Clear, descriptive name that reflects the nature of the materials Description Brief explanation of what types of materials belong in this group Best Practices for Fields

- Use consistent naming conventions

- Avoid overly technical terms

- Consider using a numbering or prefix system

- Keep descriptions clear and concise

- Include relevant categorization criteria

The form shows these required fields:

- Click + Save to create the material group once you've completed all required information:

Method 2: Import from CSV File

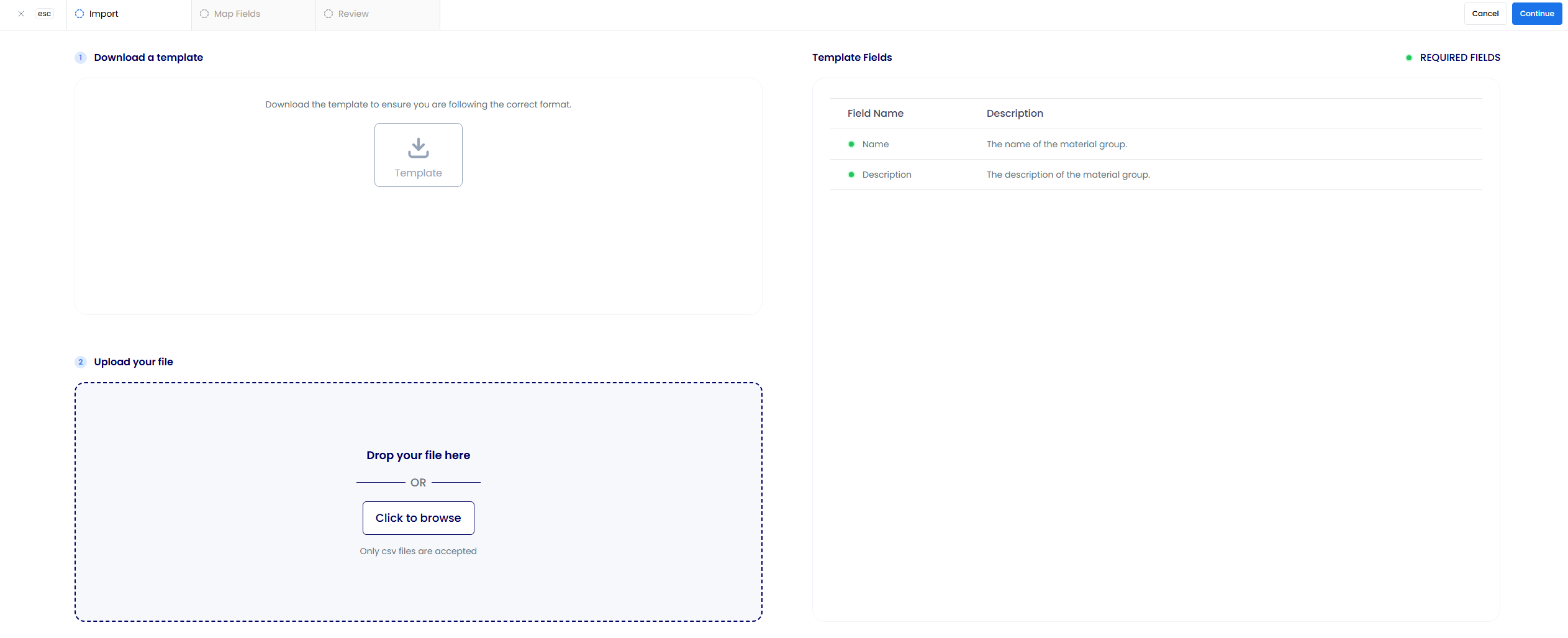

For bulk creation of material groups, you can import them using a CSV file:

- Click the + Import button to start the CSV import process:

-

Choose your import approach:

Option A: Upload your existing CSV file with the required template fields:

Option B: Download the CSV template by clicking the template button to get the correct field headers:

-

Click + Continue once you've uploaded your CSV file.

-

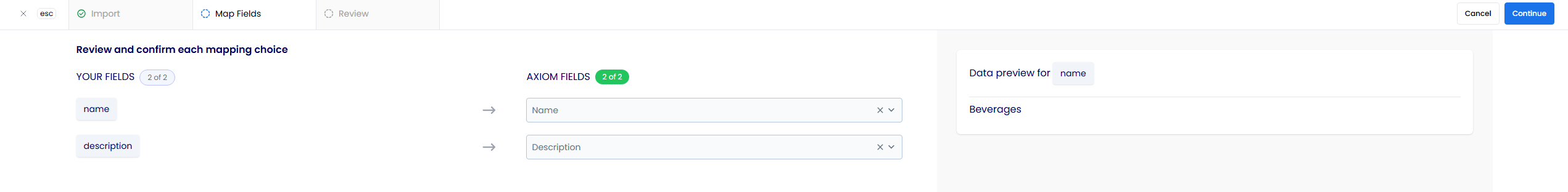

Verify field mapping - Ensure all your fields are highlighted in green, indicating they're properly mapped to the system. Then click + Continue:

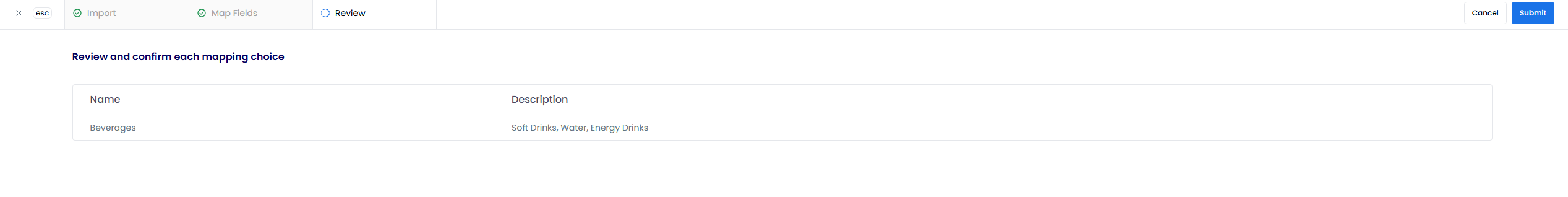

- Review your data - Give your material groups a final review before submitting them to the system. This preview shows exactly what will be imported:

Best Practices

Naming Conventions

- Use clear, descriptive names that reflect material characteristics

- Maintain consistent naming patterns across groups

- Consider including category prefixes (e.g., RAW-, FIN-, PACK-)

- Avoid abbreviations unless widely understood

- Keep names concise but meaningful

Organizational Strategy

- Group materials by function, supplier, or other relevant criteria

- Balance the number of groups and materials per group

- Avoid creating too many groups with few materials

- Similarly, avoid having too few groups with many materials

- Review and adjust grouping strategy as needs evolve

Implementation Tips

- Start with your most common material categories

- Create a standard process for new material assignment

- Train staff on the grouping system and its importance

- Regularly review and maintain group structure

- Document group purposes and criteria

CSV Import Best Practices

- Use the provided template to ensure correct formatting

- Verify data accuracy before importing

- Use consistent data formats across all rows

- Include clear descriptions for each group

- Review mapped fields carefully before import

When creating material groups, consider your reporting needs. Groups that align with how you analyze and report on inventory will make it easier to track performance and make decisions.

- Overview

- Key Features

- Benefits

- Operational Efficiency

- Inventory Management

- Business Intelligence

- Creating Material Groups

- Method 1: Manually Add a New Group

- Required Fields

- Best Practices for Fields

- Method 2: Import from CSV File

- Best Practices

- Naming Conventions

- Organizational Strategy

- Implementation Tips

- CSV Import Best Practices