Vendor Materials

Learn how to create and manage the bridge between your internal inventory materials and supplier products for efficient procurement and inventory management.

Overview

Vendor Materials create essential connections between your internal inventory catalog and supplier products. This mapping helps:

- Ensure accurate ordering

- Simplify procurement processes

- Manage unit conversions

- Track supplier relationships

- Maintain product consistency

Key Features

- Material Mapping: Link internal materials to supplier products

- Unit Conversion: Handle different measurement standards

- Multiple Identifiers: Support various product codes

- Barcode Support: Enable quick product scanning

- Supplier Integration: Maintain vendor relationships

Core Components

Identification Methods

- Vendor Material Code: Supplier's unique product identifier

- Manufacturer Part Number: Original manufacturer's code

- Barcodes: Multiple scanning options

- Internal Reference: Your material catalog link

Unit Management

- Vendor Units: How suppliers sell products

- Internal Units: How you track inventory

- Conversion Rules: Mathematical relationships

- Rounding Control: Precision settings

Managing Vendor Materials

-

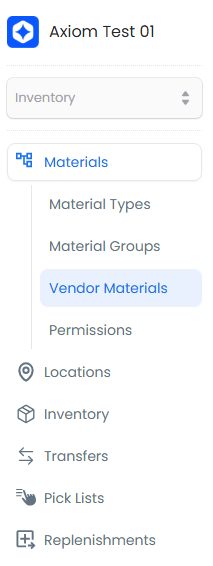

Access vendor materials:

- Click "Inventory" on the landing page

- Select "Vendor Materials" from menu

-

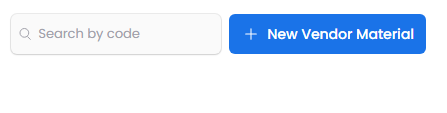

Add new vendor material:

- Click "+ New Vendor Material"

-

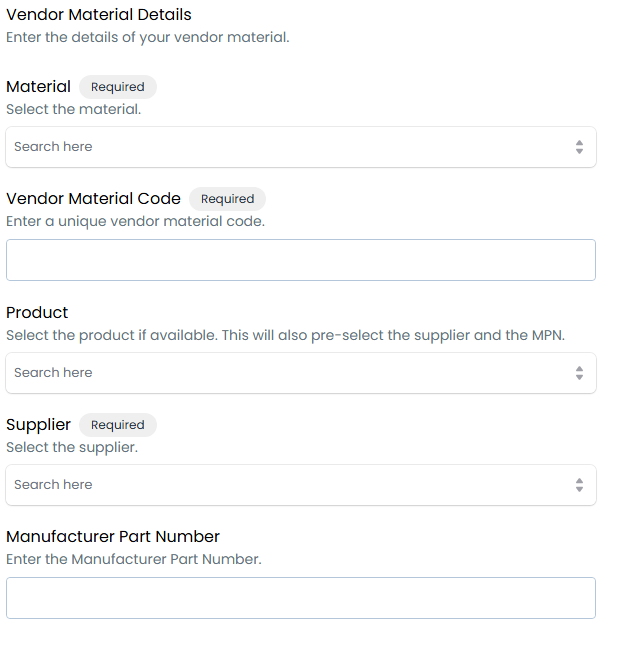

Enter material details:

Required Fields

Field Description Material Select the internal material this vendor product corresponds to Vendor Choose the supplier who provides this material Vendor SKU Enter the supplier's unique identifier for this product Unit Price Specify the cost per vendor unit of measure Optional Fields

Field Description Manufacturer Part No. Original manufacturer's identification number Vendor Unit Unit of measure used by the supplier Conversion Factor Mathematical ratio between vendor and internal units Barcodes Multiple barcode types and values for scanning Properties Additional attributes specific to this vendor's version

Best Practices

Material Setup

- Verify material specifications with suppliers

- Document any variations from standard products

- Keep supplier catalogs up to date

- Track changes to vendor specifications

- Maintain accurate pricing information

Unit Conversions

- Double-check conversion factors

- Document special conversion cases

- Test conversions in practice

- Monitor rounding precision

- Update when packaging changes

Identification Management

- Use consistent code formats

- Maintain current barcodes

- Document identifier changes

- Verify codes with suppliers

- Avoid duplicate records

Supplier Integration

- Keep vendor details current

- Track supplier changes

- Document communication

- Monitor product consistency

- Maintain pricing history

Common Issues

Conversion Problems

- Verify factors with suppliers

- Check rounding settings

- Test with sample quantities

- Document special cases

- Monitor high-volume items

Material Matching

- Use clear naming conventions

- Maintain complete documentation

- Check specifications carefully

- Verify with suppliers

- Update when products change

TIP

When setting up unit conversions, always verify the conversion factors with your supplier and test them with real quantities. It's easier to catch conversion errors during setup than after inventory transactions have occurred.